- Home

- Compacts

- Gators

- Lawn & Garden

-

New

- John Deere Products

- Ferris

- Stihl

- Home & Workshop Accessories

- John Deere Financial

-

Additional Product Lines

- Berlon Attachments

- Calumet Liquid Manure Handling

- CID Attachments

- Dawn Equipment

- Degelman

- EZ Trail

- FAST Sprayers

- Frontier

- HayBuster

- J&M Manufacturing

- Loftness

- Maurer

- Meyer's Equipment Manufacturing

- Meyer Farm Equipment

- Norden Mfg. Accumulators and Grabbers

- Protero

- Premier Portable Buildings

- Walinga

- Westendorf

- Yetter

- Inventory

- Departments

- Online Parts

- About

- John Deere Specials

- Promotions & Events

- Waupun 920-324-3537

- Beaver Dam 920-887-2728

- TOLL FREE: 800-236-3768

Search Inventory

Search Products & Site

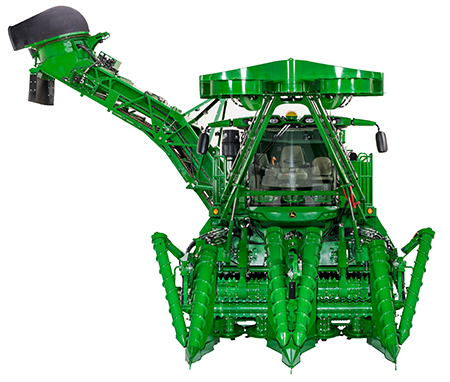

John Deere CH950 Sugar Cane Harvester

Features

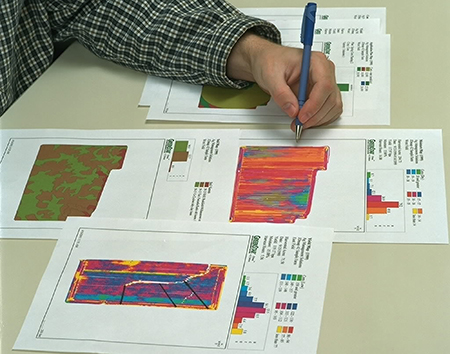

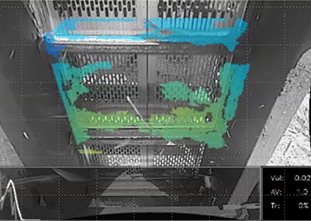

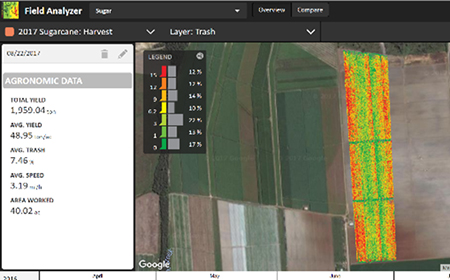

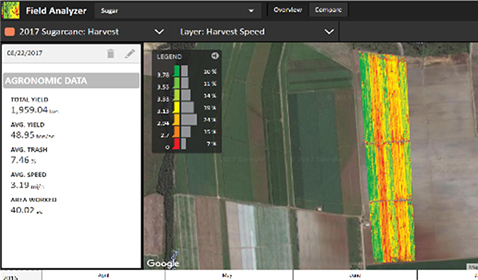

Harvest Monitor™ with SmartClean™ system enables cost saving decisions on harvesting and farming practices

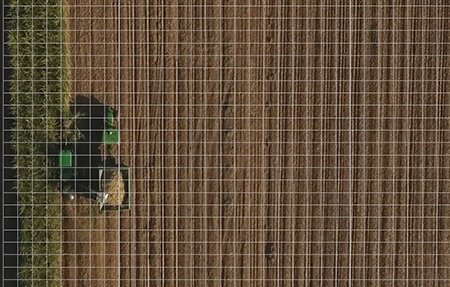

Double productivity without increasing speed

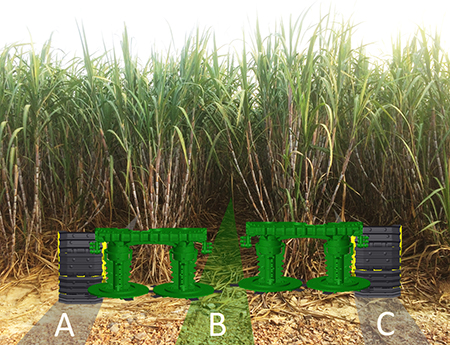

Improved yield with controlled traffic

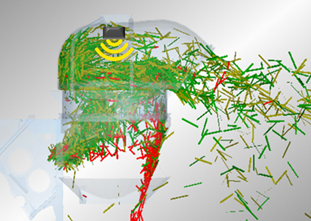

Reduce cane loss with the redesigned cleaning system

Reduce downtime during the season with larger, more robust components

Efficiently harvest two rows of cane independently using the RowAdapt™ system

Key Specs

| Engine Make | John Deere |

|---|---|

| Standard power @ 2100 rpm | 360 kW 485 hp 490 CV |

| Cooling system type | Automatically controlled, hydraulically driven reversing cooling fan |

| Fuel capacity | 1135 L 300 gal. |

| Standard chain and shoes | Sealed chain Shoes: 40.6 cm 16 in. |

| Maximum whole topper reach | 4.2 m 13.75 ft |

| Crop dividers: Float control | Automatic float control |

| Basecutter: Standard disc diameter | 58.4 cm 23 in. |

| Chopper: Standard blade configuration | Ten blade (five per drum), differential |

| Fan diameter | 1.5 m 5 ft |

Engine

| Make | John Deere |

|---|---|

| Model | 6136NW301 |

| Family | |

| Emission certification | Tier 3/Stage III A |

| Standard power @ 2100 rpm | |

| Standard power @ 2000 rpm | |

| Standard power @ 1900 rpm | 360 kW 485 hp 490 CV |

| Standard power @ 1700 rpm | 400 kW 540 hp 544 CV |

| Optional engine model | 6136NW401 |

| Optional engine emission certification | Final Tier 4/Stage IV |

| Optional power @ 2100 rpm | 420 kW 567 hp 572 CV |

| Optional power @ 2000 rpm | 440 kW 595 hp 600 CV |

| Cylinders | Inline six, wet sleeves |

| Displacement | 13.6 L 830 cu in. |

| Injection pump | Electronically controlled |

| Aspiration | Turbocharger with air-to-air aftercooling |

| Engine speeds | Low idle 800 rpm Full throttle 1900 rpm |

| Alternator | 200 amp 12 V |

Cooling system

| Type | Automatically controlled, hydraulically driven reversing cooling fan |

|---|

Transmission

| Type | Two hydrostatic pumps providing variable speed |

|---|---|

| Track machine travel speed | 0 to 9.0 km/h 0 to 5.6 mph |

Brakes

| Parking | Multiple wet disk, spring applied hydraulic released |

|---|

Capacities

| Fuel | 1135 L 300 gal. |

|---|---|

| Diesel Exhaust Fluid (DEF) (Tier 4 Engine only) | 78.2 L 20.7 gal. |

| Hydraulic oil | 309 L 81.6 gal. |

Tracks

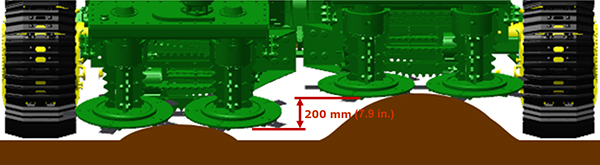

| Sprocket | Five-segment, bolt-on sprocket |

|---|---|

| Track guides | Welded guides with bolted wear plates |

| Rollers | Eight bottom rollers and two carrier rollers |

| Standard straight track shoe width | |

| Standard track chain | |

| Track tread width | Standard: 2.75 m 9 ft Optional: 3 m 9.83 ft |

| Standard chain and shoes | Chain and shoes, option 1 Sealed and chain with 560-mm (22-in.) bent shoes for 3-m (9.83-ft) tread option only Sealed and lubricated chain with 406.4-mm (16-in.) bent shoes |

| Optional bent track shoe widths | |

| Optional track chain |

Cab and controls

| Air conditioning | Pressurized cab with air conditioning and heating |

|---|---|

| Front-tipping cab | |

| Seat | Air suspension with swivel |

| Radio | Standard premium with Bluetooth® wireless |

| Emergency shut-off switch | |

| Pressurized cab | |

| GPS guidance | AutoTrac ready standard |

| Connectivity | JDLink™ ready |

| Speedometer | |

| Data management |

Lights

| Standard | |

|---|---|

| Optional | |

| Cab | Four halogen head lights and four working light-emitting diode (LED) lights |

| Auxillary for loading | Four LED lights |

| Service | Two LED lights on topper boom and two halogen lights on engine/cooling package compartment |

Topper

| Drive | Hydraulic, reversible |

|---|---|

| Shock absorption | Nitrogen accumulator |

| Maximum whole topper reach | 4.2 m 13.75 ft |

| Severing disc | Eight bolt-on blades |

| Whole topper | |

| Shredder topper | |

| Extended width whole topper |

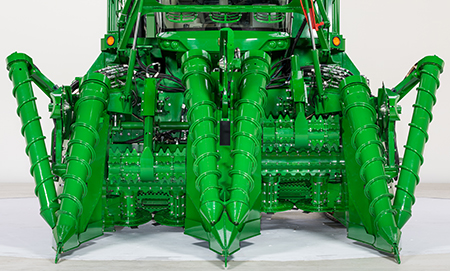

Crop dividers

| Type | |

|---|---|

| Crop divider assemblies | Two side assemblies and one center assembly |

| Center crop divider assembly scrolls | Includes two inside scrolls |

| Side crop divider assemblies scrolls | Includes one inside and one outside scroll each |

| Scrolls | |

| Drive | Hydraulic, reversible |

| Inside scrolls approach angle | 46 degree (angle) |

| Factory hard surfacing | Skirts, slip-on shoes, toes |

| Float control | Automatic float control |

| Tilt control | Hydraulic |

Crop divider knives

| Side knives | Two |

|---|---|

| Center knife | One |

| Drive | Hydraulic, reversible |

| Height control | Hydraulic |

| Blades | Three bolt-on blades per disk |

Knockdown rollers

| Knockdown roller assemblies | Two assemblies consisting of one front and one lower roller each |

|---|---|

| Drive | Hydraulic, reversible |

| Manual height adjustment | |

| Hydraulic height adjustment | Synchronized front and lower roller travel |

Basecutter

| Basecutters | Center to center distance 140 cm 55.1 in. Two independent |

|---|---|

| Drive | Hydraulic, reversible |

| Height control | Automatic contour basecutter height control |

| Discs per box | Two |

| Legs | Vertical with bolt-on wear plates |

| Gearbox housing | Cast |

| Standard drive | |

| Optional drive | |

| Standard disc diameter | 58.4 cm 23 in. |

| Optional disc diameter | |

| Discs center distance | 63 cm 24.8 in. |

| Number of blades per disc | Five |

Buttlifter

| Buttlifters | Two |

|---|---|

| Drive | Hydraulic, reversible |

| Type | Four-bar open |

Feedrollers

| Drive | Hydraulic, reversible drive |

|---|---|

| Number of rollers | |

| Feed train assemblies | Two front split feed trains and one rear common feed train |

| Feedroller train | Each feed train has upper floating rollers and lower feedrollers |

| Front split feed trains number of rollers | Each feed train has four upper rollers and four lower rollers including the buttlifter |

| Rear feed train number of rollers | Three upper rollers and four lower rollers including the transition roller |

| Bearing location | External |

Chopper

| Drive | Hydraulic, reversible |

|---|---|

| Drum center distance | 38.1 cm 15 in. |

| Bearing location | External |

| Blade width | 9.5 cm 3.74 in. |

| Blade configuration | Standard 10 blade (five per drum), overlap Option 1 Eight blade (four per drum), overlap |

| Sill roller | Standard |

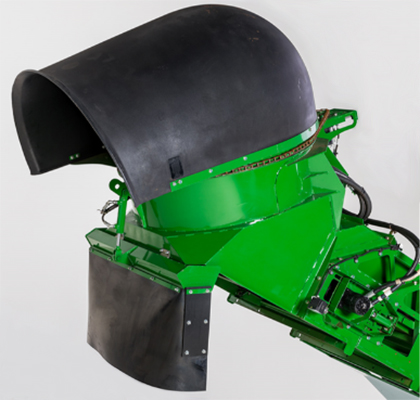

Primary extractor

| Fan drive | Hydrostatic, variable speed |

|---|---|

| Fan diameter | 1.5 m 5 ft |

| Fan number of blades | Four |

| Maximum fan speed | 930 rpm |

| Hood rotation | Hydraulically controlled |

| Wear ring | Highly abrasive-resistant steel |

Elevator

| Chain adjustment | Grease cylinder |

|---|---|

| Sprocket drive | Hydraulic motor driven, reversible |

| Width | 112 cm 44.1 in. |

| Elevator swing | Hydraulically controlled, trunnion cylinders |

| Total swing angle | 170 degree (angle) |

| Shock absorption | Nitrogen accumulator |

| Slat height | |

| Optional elevator extensions |

Secondary extractor

| Fan drive | Hydraulic |

|---|---|

| Fan number of blades | Three |

| Fan diameter | 1.22 m 4 ft |

| Hood rotation, degrees | |

| Bin flap position | Hydraulically controlled |

Weight

| Machine weight | 35,545 kg 78,363.2 lb Weight may vary with options |

|---|

Additional information

| Date collected | 17 January 2020 |

|---|

Would you like more information?

Free Parts Delivery to

Drop Boxes!